About Client

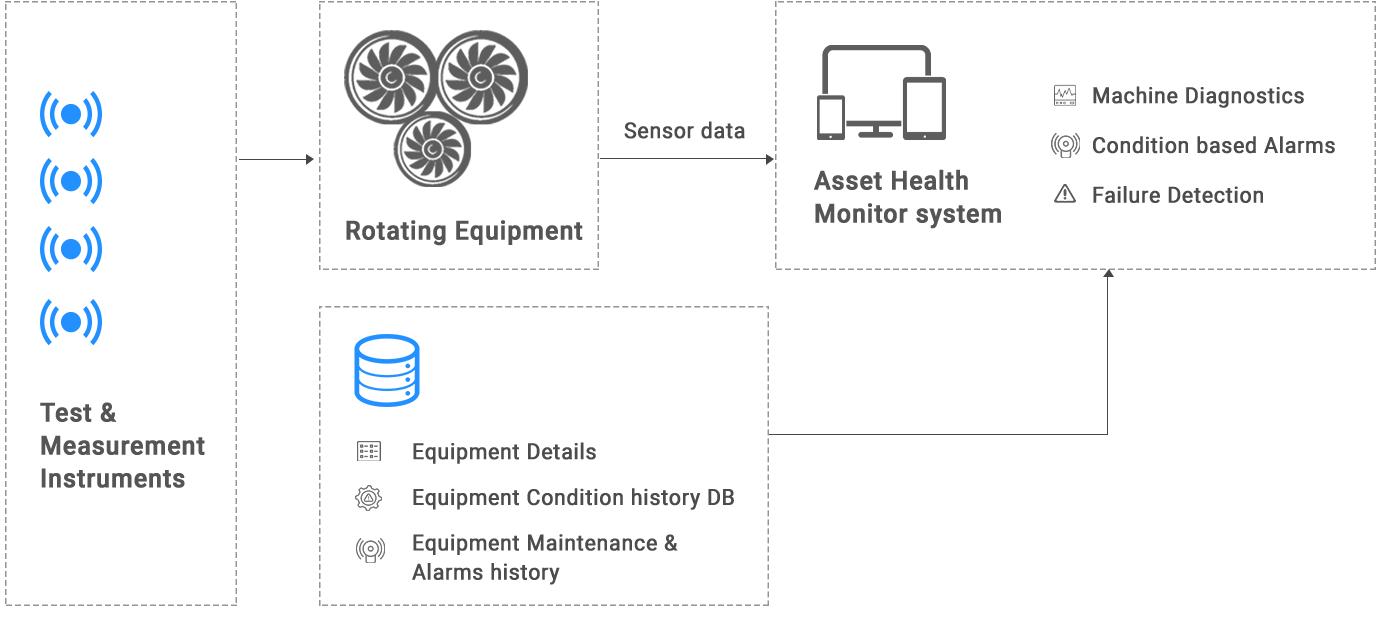

The instruments engineering company empowers leaders in the industrial equipment & renewable energy industry. They provide smart sensors & hardware, to help industrial Enterprises reduce their equipment maintenance costs, improve machine yield, increase machine uptime and ensure process quality. Their smart hardware solution -

- captures vibration & other environmental data in real time through sensors installed on various components of industrial equipment like Turbines, pumps

- processes the high volume, high frequency data to monitor, analyze & alert about machine condition

- generates insights to help predict downtimes and thereby enable customer to maintain systems health & equipment efficiency

Challenge

Sensors capture physical data from equipment at a high frequency which is then managed and analysed locally on desktop based systems. Their end users then process the data locally on their desktops, and manually create visibility into equipment conditions & their failure modes.

Using the existing solution resulted in Manual, inaccurate and time-consuming fault detection. They decided to automate data collection, enable cloud-based data processing as well as AI-based fault detection while making it more data driven instead of age-old rules based. There were a few challenges to this –

- Traditional predictive tools are hard to scale and deploy

- Need predictive analytics to be embedded within their application

- Data preparation, cleansing, choosing the right algorithm, training it and validating needs expertise with modern data platforms

- The platform and application need to easily integrate with all hardware products

This required a well thought data engineering approach to build robust Industrial IoT analytics solution, for capturing, managing and analyzing real-time data.

Solution

A minimum viable product approach was adopted to quickly engineer and build a data platform that holds the power to connect millions of sensors globally and enable industrial systems and equipment to be more intelligent about their failures, availability & operating efficiency.

Testing and monitoring industrial systems

Testing and monitoring industrial systems

The Platform developed

Saviant partnered with the instrument engineering company in developing the desired intelligent data platform for their next decade vision. With a team of technology consultants that included Data Analytics / Machine Learning consultants, Technology Architect, IoT consultants, a platform was designed which enables

- High performance data engineering and automates capturing data, orchestration, and analysis

- Machine Learning models to replace age-old “if-then rules” method of fault detection

- Accurate & timely alerts & notifications about the failure conditions & alarms

Key Results

The solution enabled more efficient and automated fault diagnosis. Timely preventive actions could be taken to avoid downtimes and improve productivity. Real-time insights were easily made available to the end customers on a single platform that helped the Instrument Engineering company to offer Intelligence-as-a-service.