HVAC equipment are critical to maintain thermal comfort and air quality. HVAC industry forms the backbone for operations across manufacturing, residential and commercial establishments. The HVAC-Equipment company, our client, is the top manufacturer in Middle East; exporting goods and services to more than 50 countries worldwide.

With over 3 decades of experience, they have maintained their market leadership as a designer and manufacturer of sophisticated, high quality commercial and industrial HVAC equipment.

They are globally known to offer a diverse variety of first-rate heating, ventilation and air conditioning (HVAC) equipment.

Their customers span across entertainment, educational, healthcare, industrial, malls and other establishments. Some of the products which see high demand include air handlers, chillers, dry cooler unit, exhaust fans and split units.

Challenges and Opportunities

As a manufacturing hub, HVAC-Equipment company is aided with various enterprise solutions helping them operate and manage their operations, manufacturing, production, marketing, finance, sales, etc. Since these systems are acting in silos, the data sources become discreet to visualize.

The excel-driven reporting process made it difficult to take informed decisions. They wanted to explore advanced data platform and business intelligence solutions; to analyze data, which was currently consumed on excel from different data source.

They wanted to upgrade the current tabular reports to show critical KPIs using intuitive dashboards. These dashboards will be significant to the HVAC-Equipment company to take informed decisions and get early and detailed insights.

Saviant Partnership with HVAC-Equipment company

The HVAC-Equipment company is undergoing Digital Transformation to modernize and re-engineer their existing legacy application. As part of the overall digital transformation journey, the project was divided into phases. They partnered with Saviant to implement a robust BI platform for their manufacturing operations.

Using Power BI platform, the operations & production data was converted into production dashboard with rich visuals to showcase critical KPIs. This approach was the first step towards building unified data platform to create a single source of truth.

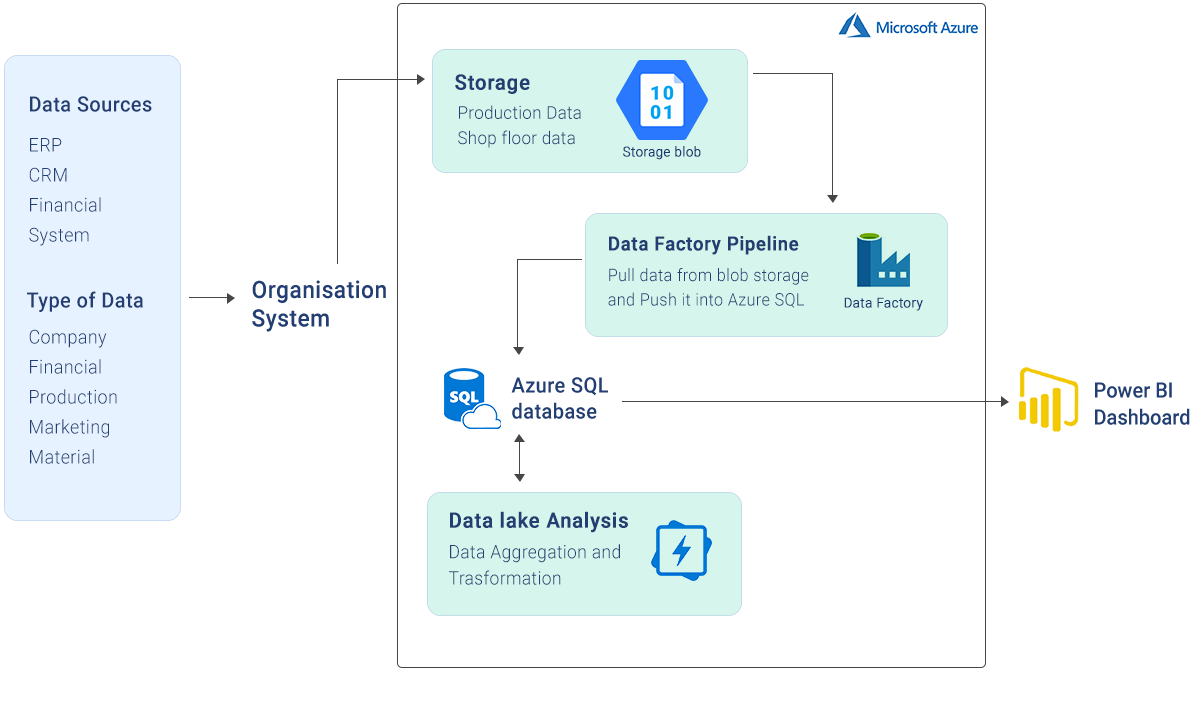

Production Analytics & Business intelligence solution architecture diagram

Production Analytics & Business intelligence solution architecture diagram

The transformation journey began with understanding the gaps in efficiency at Assembly, Production, and Shipping of Manufacturing factory. The HVAC-Equipment company implemented Production Analytics solution using production data and identified the right KPIs, where Saviant’s Data Analytics consulting team ensured right fit of technology and solution approach.

Advanced BI dashboards using Power BI for Production Analytics consisted of:

- Executive and Sales analytics

- Production status and process insights

- Project summary and current status

- Shipping status and insights

Project wise assembly summary was now equipped with RAG Indicators to highlight quick status of actual/planned events of start and finishing of various production line operations. Average days per stage in the production/ shipping/ sales order helped the stakeholders to understand the stages/processes slowing down the production line or hampering overall productivity. The completion rate instigated the workforce to promptly work upon the target on time.

Executive Sales Summary provided insights on the most lucrative market, why a certain workload has been highest on a certain sales member, why there were certain number of disapproved tasks and more.

Executive Production Summary dashboards brought into notice how project was impacted by delays and why there was production shortage.

Executive Shipping Summary displayed red indicators for dispatches which were stuck unnecessarily for a longer than expected time. The details of task owner workload also help identify any delays in the process.

Power BI Dashboard for Production Analytics

Power BI Dashboard for Production Analytics